Introduction

In the tricky world of semiconductor manufacturing, cord bonding stands as a pivotal job. This approach serves to determine electric connections among the chip and its kit, making certain reliability and efficiency in electronic instruments. Among a number resources used for wire bonding, gold and copper are the most admired contenders. Each cloth possesses specific attributes that make contributions to their efficiency in one of a kind applications. In this text, we're going to delve into The Advantages of Gold vs Copper in Wire Bonding, exploring their qualities, merits, drawbacks, and suitability for countless varieties of wire bonding procedures.

Understanding Wire Bonding Process

The twine bonding process entails connecting skinny wires from a semiconductor die to its bundle or substrate utilising mechanical and thermal calories. This approach is a very powerful for developing potent electric connections that resist operational stresses. The wires would be made from countless elements, with gold and copper being the so much by and large used.

How Wire Bonding Works

Wire bonding in most cases employs both ball bonding or wedge bonding procedures. In ball bonding, a ball is formed on the conclusion of the cord in the past it truly is attached to the bond pad on the semiconductor die. Conversely, wedge bonding contains due to a wedge-fashioned software to create an ultrasonic bond between the wire and pad.

What Is Wire Bonding?

Wire bonding is a essential interconnection era used in the main in semiconductors. It helps communication among chips and their applications while asserting low resistance connections mandatory for software performance.

Types of Wire Bonding Techniques

Ball Bonding Wedge Bonding Ribbon BondingEach strategy has its blessings centered on layout specifications and material homes.

The Role of Materials in Wire Bonding

When choosing materials for wire bonding, concerns like check, reliability, conductivity, and thermal homes come into play. Let's explore how gold and copper degree up against every single other.

Gold Wire Bonding: Characteristics and Benefits

Gold twine bonding has been a general within the industry on account of a couple of key advantages:

- Excellent Conductivity: Gold's prime electrical conductivity guarantees minimal resistance. Corrosion Resistance: Gold does no longer oxidize actual or corrode, which raises long-time period reliability. Thermal Stability: Gold maintains solid features less than various temperatures.

Applications of Gold Wire Bonding

Gold twine is predominantly applied in excessive-reliability packages which include aerospace electronics and clinical contraptions resulting from its physically powerful performance.

Copper Wire Bonding: Characteristics and Benefits

Copper has gained popularity not too long ago thanks to its high-quality houses:

- Cost-Effectiveness: Copper is tremendously more cost-effective than gold; for that reason, it offers economic reward. High Electrical Conductivity: Although fairly much less than gold's, copper's conductivity continues to be amazing. Strength: Copper bonds are typically routinely superior than those made with gold.

Applications of Copper Wire Bonding

Copper is extensively used in user electronics wherein rate-effectivity is paramount devoid of compromising too much on reliability.

Comparative Analysis: Gold vs Copper in Wire Bonding

Conductivity Comparison

Both gold and copper show fine conductivity; then again:

| Material | Electrical Conductivity (S/m) | Cost in keeping with kg ($) | |----------|-------------------------------|------------------| | Gold | 45 x 10^6 | 60 | | Copper | Browse around this site fifty nine x 10^6 | 8 |

This desk illustrates why copper may be greater desirable from a fee angle in spite of relatively scale back conductivity.

Reliability Factors

Reliability is obligatory whilst settling on substances for targeted functions:

- Gold excels in environments likely to corrosion. Copper’s susceptibility to oxidation calls for shielding measures but offers superb mechanical strength while wisely processed.

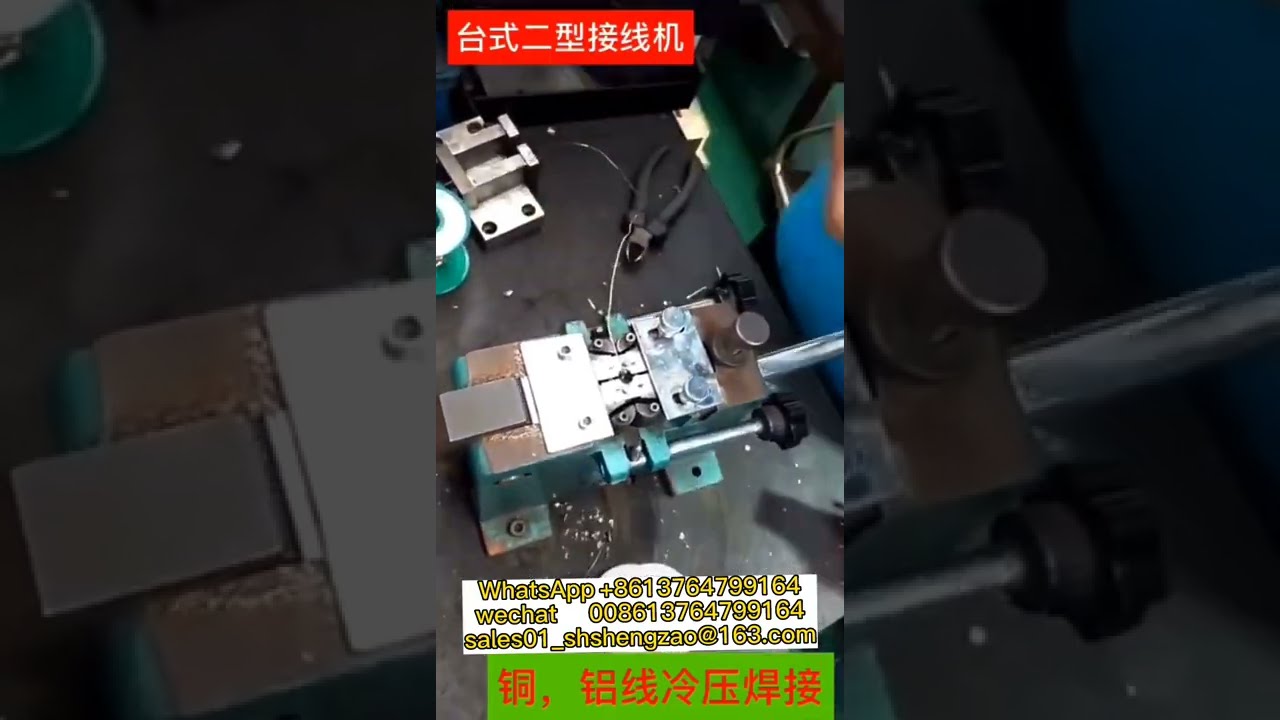

Wire Bonding Equipment Considerations

To obtain greatest outcome in each types of cord bonding processes, specialised gear performs a quintessential function:

Wire Bonding Machine Types

Manual Semi-Automatic Fully AutomaticEach class grants various stages of manage over the bond best.

Wire Bond Inspection Techniques

Ensuring good quality keep watch over at some point of cord bonding contains alternative inspection tactics inclusive of:

- Visual Inspection X-ray Analysis Pull Testing

These assessments help determine prospective trouble early on.

Wire Bond Failure Analysis

Understanding standard failure modes related to both gold and copper twine bonds can support mitigate dangers:

Common Failure Modes

Oxidation Mechanical Stress Thermal CyclingAnalyzing those causes allows engineers pick out accurate constituents established on software stipulations.

Wire Bond Quality Control Measures

Implementing strict exceptional regulate measures in the time of creation guarantees long-time period reliability:

Techniques for Quality Assurance

Automated Inspection Systems In-line Testing Methods Detailed Documentation ProcessesThese measures are vital for declaring prime requisites across all cord bonding packages.

FAQs About Gold vs Copper in Wire Bonding

1. What are the most important distinctions between gold and copper twine bonding?

Gold delivers finest corrosion resistance even as proposing suitable conductivity however comes at a top value point as compared to copper which is extra low-cost yet can oxidize if now not precise taken care of.

2. Which materials is more good for car functions?

While both should be would becould very well be used with ease in automobile electronics, gold's resistance to environmental reasons makes it most effective for prime-reliability programs inside this area.

3. How does the fee have an impact on resolution between gold and copper?

For excessive-volume creation in which fee discounts are critical, manufacturers in many instances lean in the direction of copper; having said that, applications requiring toughness can also justify making use of gold regardless of upper bills.

four. What inspection ways are encouraged in the course of twine bonding?

Common tricks comprise visual inspections blended with automatic X-ray checking out to confirm each bond meets good quality ideas effectively previously shifting forward with production processes.

five. Can I use equally materials interchangeably?

Interchangeability isn’t really useful with no cautious consideration as every materials has distinguished properties affecting bond capability under a good number of circumstances—seek advice remarkable engineering hints earlier making substitutions!

6. Are there any techniques getting better those applied sciences?

Yes! Recent developments embrace superior processing methods tailored especially for copper that give a boost to its overall performance features whilst minimizing oxidation disadvantages right through production cycles!

Conclusion

In summary, expertise The Advantages of Gold vs Copper in Wire Bonding reveals significant insights into materials collection dependent on application specifications—either play considered necessary roles inside electronics production landscapes as we speak! While gold’s remarkable reliability shines simply by selected sectors like aerospace or medical gadgets due in large part due its corrosion-resistant nature; conversely low-expense picks similar to copper dominate purchaser electronics markets pushed with the aid of fiscal elements! Ultimately making a choice on properly among them hinges upon balancing efficacy against budget constraints—a mission made less difficult via grasped information shared here!

This finished exploration not merely highlights key distinctions however additionally fingers pros with precious knowledge pivotal in the direction of making told picks throughout dissimilar industrial contexts—indirectly shaping long term advancements inside this ever-evolving domain!