Introduction

In the fast-paced world of electronics production, knowledge distinctive bonding ways is essential for producing legit and powerful devices. One such method that has gained considerable traction in latest years is wedge bonding. This article will delve into the authentic-global programs of wedge bonding, exploring its advantages, systems, and alternative sectors it serves. From semiconductors to scientific units and every little thing in among, we’ll have a look at how this science is reworking industries although keeping up prime ideas in best and reliability.

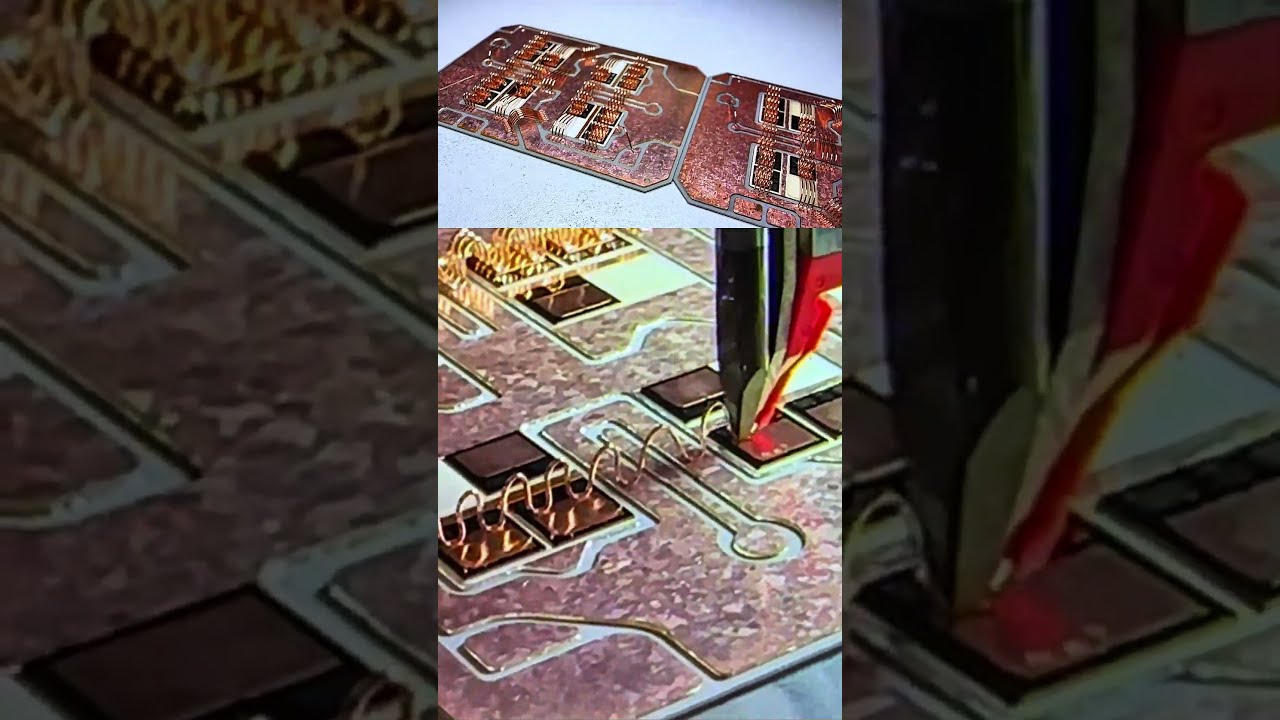

What is Wedge Bonding?

Wedge bonding is a twine bonding method involving a wedge-formed tool that creates connections among semiconductor devices and substrates. It’s greatly used in a number of fields through its capability to furnish robust electrical interconnections with minimum mechanical rigidity. Understanding the nuances of this method can be offering insights into why it has become a general possibility among producers.

How Wedge Bonding Works

The strategy starts off with positioning the twine over the bonding pad at the semiconductor system. The wedge instrument applies ultrasonic potential or warmth (depending on no matter if it can be ultrasonic or thermosonic wedge bonding) to facilitate metallic drift, growing a forged bond. This manner facilitates for incredible keep watch over over bond parameters, contributing to excessive reliability.

Wedge Bonding vs. Other Bonding Techniques

When evaluating wedge bonding with other programs like ball bonding or flip-chip soldering, numerous components come into play:

Cost Efficiency: Wedge bonding ordinarily requires much less cloth than different tools. Thermal Stability: Wedge bonds can withstand increased temperatures than a few selections. Mechanical Strength: The bond created due to this means tends to be greater robust beneath mechanical strain.Types of Wedge Bonding Methods

There are numerous types of wedge bonding strategies tailor-made for distinctive purposes:

1. Ultrasonic Wedge Bonding

This process utilizes ultrasonic electricity to create bonds at decrease temperatures, making it accurate for delicate constituents.

2. Thermosonic Wedge Bonding

Combining heat and ultrasonic energy, thermosonic wedge bonding enhances fabric go with the flow, resulting in more desirable bonds.

three. Deep Access Wedge Bonding

Ideal for functions requiring deep get entry to points wherein general methods may battle.

4. Insulated Wedge Bonding

Incorporates insulation round the wire for more suitable defense in sensitive environments.

Real-World Applications of Wedge Bonding

Now that we be aware of what wedge bonding is and its categories, allow’s explore its real-global functions throughout a considerable number of industries:

1. Semiconductor Manufacturing

Wedge bonding performs a critical role in semiconductor units' packaging. Its skill to handle fantastic pitch leads makes it splendid for innovative microprocessors and reminiscence chips.

Benefits

- High-density packaging Reduced thermal resistance Enhanced electrical performance

2. Medical Devices

In the scientific box, in which reliability should be a count number of lifestyles and dying, wedge bonding guarantees at ease connections in implantable gadgets equivalent to pacemakers and sensors.

Benefits

- Biocompatibility Resistance to environmental aspects (moisture, temperature) High reliability

three. Automotive Electronics

As vehicles develop into more and more reliant on digital techniques for defense and functionality, wedge bonding bargains durable suggestions for automotive modules consisting of ECUs (Electronic Control Units) and sensors.

Benefits

- Enhanced vibration resistance Low-value production processes Improved long-time period reliability

four. Aerospace Applications

In aerospace know-how, in which weight discounts are imperative with out compromising power or reliability, wedge bonding excels by means of chopping the dimensions and weight of aspects even as sustaining functionality integrity.

Benefits

- Lightweight interconnections Resistance to excessive conditions Compliance with stringent safeguard regulations

5. LED Manufacturing

With LEDs turning Learn more here into ubiquitous in lighting ideas, riding wedge bonding improves connectivity within LED applications through supplying riskless electrical contacts that withstand thermal cycling rigidity.

Benefits

- Improved easy output efficiency Longer lifespan of LED products Enhanced thermal management

Wire Bonding Process Overview

To thoroughly delight in the significance of wedge bonding inside of its real-international packages, we would have to keep in mind the final wire bonding approach:

Preparation: Cleaning surfaces ensures most useful adhesion. Placement: Accurate positioning of wires applying complex cord bonder machines. Bond Creation: Utilizing either ultrasonic or thermosonic ways centered on utility requisites. Inspection: Visual inspection observed through non-damaging testing (e.g., pull tests) ensures bond quality. Finalization: After triumphant inspections, encapsulation or additional protective measures are utilized as considered necessary.Challenges in Wire Bonding Reliability

Despite its a good number of benefits, numerous challenges exist bearing on wire bonding reliability:

Bond Failures: Common screw ups encompass heel cracks and bond lifting using unsuitable settings or infection.

Oxidation Issues: Oxidation can weaken bonds if right precautions aren’t taken for the period of practise levels.

Environmental Factors: Moisture exposure can result in corrosion over the years; thus protective coatings are characteristically counseled.

Material Selection: Choosing between gold vs aluminum vs copper cord depends on conductivity needs as opposed to check issues.

FAQ Section

1. What elements are characteristically utilized in wedge bonding?

Wedge bonding specifically makes use of gold and aluminum wires by reason of their most excellent conductivity and ductility; copper has additionally emerged as a cheap different but comes with oxidation risks that need addressing.

2. How does one be certain that great management throughout the time of cord bonding?

Quality manage comprises assorted steps including visual inspections submit-bond construction as well as pull assessments that measure bond power towards common thresholds outlined by way of trade concepts like JEDEC.

3. Can you clarify the differences between ball bonding and wedge bonding?

Ball bonding paperwork a spherical connection utilizing heated balls on the end of wires even as wedge bonds use flat surfaces pressed jointly; each and every has special reward relying on utility standards like pitch length or environmental stipulations confronted for the period of operation.

4. Is there any tuition possible for discovering cord bonding systems?

Yes! Numerous enterprises be offering each on line programs (generally available as PDFs) such as reasonable workshops designed specifically focusing on engineers seeking deeper awareness approximately potent practices within alternative contexts like semiconductor packaging or automobile electronics integration tactics!

5.What are some known defects encountered throughout wire bond processing?

Common defects consist of incomplete bonds due lack precise pressure calibration utilized all through setup premier competencies mess ups linked weak connections diagnosed by means of specified visible inspection protocols accepted throughout manufacturing lifecycle phases!

6.Are there any improvements these days being researched on the topic of improving present techniques & technologies applied as we speak?

Absolutely! Researchers hold exploring developed substances consisting of automated tactics incorporating AI-pushed controls aimed optimizing efficiency metrics alongside chopping costs regular linked basic procedures employed traditionally across loads of sectors noted previous!

Conclusion

Wedge bonding represents a pivotal technologies across many sectors—semiconductors being simply one instance—by presenting riskless connections important for software functionality at the same time navigating closer to ever-increasing demands referring to density compactness durability estimated from modern-day electronic designs! As brands maintain adapting their approaches alongside evolving customer expectations surrounding high-quality coverage criteria rising developments suggest even brighter futures look forward to those inclined include thoughts shaping panorama ahead!