Introduction

In the short-evolving international of electronics and semiconductor manufacturing, the wire bonding procedure stands as a needed process for making respectable electrical connections. From integrated circuits to energy modules, realizing and studying wire bonding strategies can critically toughen product functionality and reliability. This article delves into the intricate main points of wire bonding science, exploring diverse tricks, programs, equipment, screw ups, and strategies to verify most reliable outcome.

With a spotlight on useful insights and technical intensity, this finished manual goals to provide engineers, manufacturers, and pupils with the advantage mandatory to excel in wire bonding. Whether you’re a seasoned official or a newcomer within the area, gaining knowledge of wire bonding methods is critical for attaining tremendous digital assemblies.

What is Wire Bonding?

Wire bonding refers back to the strategy of connecting two metallic surfaces by way of a skinny cord that creates an electric bond. This methodology is extensively used in semiconductor amtech wire bonding packaging and electronic machine meeting to ascertain connections among chips and substrates or inside of multi-chip modules.

The Importance of Wire Bonding in Electronics

Wire bonding performs a principal function in ensuring electric conductivity and mechanical stability within electronic contraptions. Its value extends across dissimilar industries:

- Semiconductors: Essential for chip-to-chip communication. Automotive Electronics: Critical for safe practices platforms like airbags. Medical Devices: Ensures reliability in life-saving units.

How Wire Bonding Works

The cord bonding job comprises a number of steps:

Preparation: The surface is cleaned to eliminate contaminants. Bonding: A warmth source (ultrasonic or thermosonic) softens the metal on the bond interface. Formation: The twine is pressed onto the floor due to a bonding instrument. Cooling: The bond solidifies because it cools down.Understanding how these stages engage allows for engineers to optimize stipulations for more beneficial bond first-rate.

Types of Wire Bonding Techniques

When discussing twine bonding ways, it's critical to be aware of that there are several equipment tailored for varied purposes:

Ball Bonding Process

Ball bonding contains creating a small ball on the cease of the wire before it makes contact with the substrate. This manner is characteristically used on account of its efficiency and reliability.

Advantages:

- High power bonds Suitable for superb pitch applications

Disadvantages:

- Requires suitable control of parameters equivalent to warm and pressure

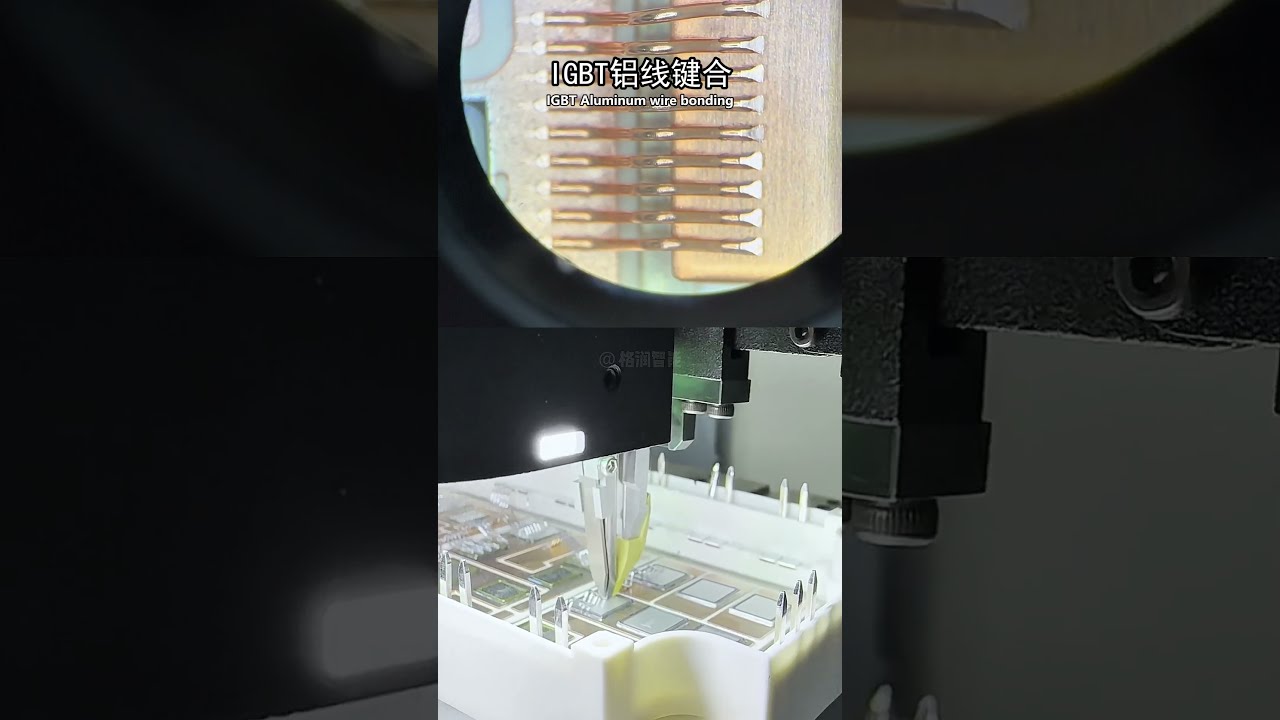

Wedge Bonding Process

Wedge bonding makes use of a wedge-formed device that presses in an instant onto the material floor devoid of forming a ball. This strategy is in many instances preferred while running with aluminum wires.

Advantages:

- Lower charge in comparison to gold Ideal for considerable-aspect bonds

Disadvantages:

- May now not in achieving as good a bond as ball bonding

Ribbon Bonding Technique

This method uses flat ribbons rather than round wires, allowing for enhanced surface sector contact which is able to cause stronger thermal performance.

Applications:

- Power modules High-frequency devices

Wire Bonding Equipment Overview

To effectually execute any wire bonding methodology, targeted equipment and resources are required:

Wire Bonding Machine Types

Manual Wire Bonder- Operated manually; exact for low-extent construction.

- Combines manual input with computerized controls; can provide flexibility.

- Ideal for top-extent construction; maximizes efficiency and consistency.

Key Components of Wire Bonding Machines

| Component | Function | |--------------------------|-----------------------------------------------| | Ultrasonic Generator | Provides ultrasonic energy for bonding | | Heated Capillary Tool | Applies warmth in the course of bond formation | | Programmable Logic Control| Automates desktop operations |

Choosing the Right Wire Bonding Method

Selecting an appropriate cord bonding strategy relies upon on dissimilar aspects along with fabric houses, utility requirements, and can charge considerations.

Gold vs Aluminum Wire Bonding

When deciding among gold or aluminum wire bonding, engineers have got to examine:

- Cost implications (aluminum is in general more affordable) Required electrical qualities (gold gives you most beneficial conductivity)

Copper Wire Bonding Advantages

Copper has grow to be an increasing number of widely wide-spread because it affords astonishing electric efficiency at diminish costs compared to gold or aluminum.

Factors Influencing Selection

Application type Environmental conditions Reliability requirementsWire Bonding Applications Across Industries

The versatility of cord bonding know-how allows for it to be utilized across a considerable number of sectors:

Wire Bonding in Semiconductors

Semiconductor units depend heavily on sturdy interconnections accomplished by means of victorious wire bonding suggestions.

Key Uses:

- Chip packaging Multi-die configurations

Wire Bonding for Automotive Electronics

In car packages, in which reliability is paramount on account of defense issues, evolved cord bonding strategies are employed broadly.

Examples:

- Airbag systems Engine handle units

Wire Bonding Failure Analysis

Despite developments in era, screw ups can take place during the twine bonding activity:

Common Failure Modes

Bond Lifting: Occurs whilst inadequate strength or temperature ends up in weak bonds. Heel Cracks: Result from tension all over thermal biking. Oxidation: Contaminants also can compromise bond integrity over time.Conducting Failure Analysis

To handle those matters correctly:

Use non-detrimental trying out processes like X-ray inspection. Perform pull tests and shear assessments in most cases to be certain bond capability.Mastering Wire Bond Quality Control

Ensuring high-quality bonds is necessary in preserving product reliability:

Quality Control Techniques

Visual Inspection

Regular visible exams support seize defects early on.

Automated Inspection Systems

Implement robotic strategies outfitted with imaginative and prescient sensors for truly-time tracking.

Understanding Wire Bond Reliability

Reliability tests are central in predicting long-term performance:

Factors Impacting Reliability

Environmental Stress (temperature fluctuations) Mechanical Strain (vibration exposure)By wisdom these causes, engineers can design more resilient items thru strategic materials collection and processing prerequisites.

Advanced Topics in Wire Bond Technology

As technology evolves, so do methodologies surrounding cord bonding:

Low Temperature Wire Bonding

Emerging supplies require diversifications in usual methods—low-temperature suggestions permit victorious connections devoid of unsafe delicate additives.

Industry four.0 Integration

Adopting sensible production ideas enhances automation at some point of manufacturing strains, growing effectivity whereas decreasing human errors throughout wiring procedures.

Learning Resources on Wire Bond Techniques

For those enthusiastic about deepening their potential about wire bonding tactics:

Wire Bonding Tutorial – A finished support overlaying fundamentals due to complicated practices. Webinars & Training Programs – Online programs hosted by industry professionals imparting insights into well suited practices. Research Papers & Case Studies – Academic elements exploring today's advancements inside of this discipline.Conclusion

Mastering cord bonding programs calls for an knowledge that spans classic ideas because of stepped forward packages across a number of industries. By leveraging brand new technology alongside universal practices together with satisfactory management measures and failure prognosis exercises—engineers can ensure their products meet rigorous ideas while pushing ahead innovation limitations inside electronics manufacturing ecosystems global!

FAQs about Wire Bonding Techniques

What substances are pretty much utilized in cord bonding?

Most traditionally used fabrics comprise gold, aluminum, copper, and silver on account of their outstanding conductivity.

How does environmental control affect twine bonds?

Controlling humidity phases reduces oxidation hazards which make contributions notably in direction of recovering long-time period reliability outcomes.

What factors effect the choice between ball bonder vs wedge bonder?

Factors akin to software classification, cost constraints, and wanted bond electricity play pivotal roles the following.

li44/ol10/# What role does schooling play in helpful implementation?

Training guarantees technicians have in mind operational nuances foremost closer to fewer mistakes which in the long run helps average manufacturing high-quality advancements through the years.

6 . hr13hr13/##

In this substantial exploration into gaining knowledge of cord-bond ideas—even if you are crafting problematic microelectronics or potent automobile options—there's perpetually greater room for increase!