Introduction

In the short-evolving world of electronics and semiconductor manufacturing, the wire bonding strategy stands as a integral process for making safe electrical connections. From integrated circuits to electricity modules, awareness and gaining knowledge of wire bonding programs can extensively adorn product performance and reliability. This article delves into the intricate small print of cord bonding know-how, exploring several methods, applications, tools, failures, and options to make sure that foremost outcomes.

With a focal point on reasonable insights and technical intensity, this comprehensive handbook targets to furnish engineers, brands, and college students with the abilities beneficial to excel in cord bonding. Whether you’re a pro pro or a newcomer in the discipline, learning cord bonding methods is a must-have for reaching exquisite electronic assemblies.

What is Wire Bonding?

Wire bonding refers to the process of connecting two metallic surfaces via a thin wire that creates an electric bond. This way is commonly utilized in semiconductor packaging and digital gadget assembly to set up connections among chips and substrates or inside multi-chip modules.

The Importance of Wire Bonding in Electronics

Wire bonding plays a primary role in making certain electric conductivity and mechanical steadiness inside digital devices. Its value extends throughout dissimilar industries:

- Semiconductors: Essential for chip-to-chip verbal exchange. Automotive Electronics: Critical for safe practices approaches like airbags. Medical Devices: Ensures reliability in lifestyles-saving devices.

How Wire Bonding Works

The wire bonding technique comes to various steps:

Preparation: The surface is cleaned to put off contaminants. Bonding: A warmness supply (ultrasonic or thermosonic) softens the steel at the bond interface. Formation: The twine is pressed onto the surface through a bonding software. Cooling: The bond solidifies as it cools down.Understanding how those levels work together lets in engineers to optimize prerequisites for greater bond high-quality.

Types of Wire Bonding Techniques

When discussing wire bonding methods, it truly is obligatory to have an understanding of that there are quite a few tactics adapted for alternative programs:

Ball Bonding Process

Ball bonding includes creating a small ball at the stop of the wire earlier it makes touch with the substrate. This methodology is usually used by using its effectivity and reliability.

Advantages:

- High force bonds Suitable for high-quality pitch applications

Disadvantages:

- Requires unique control of parameters together with warmth and pressure

Wedge Bonding Process

Wedge bonding utilizes a wedge-formed instrument that presses instantly onto the drapery surface without forming a ball. This system is most often favourite whilst running with aluminum wires.

Advantages:

- Lower can charge in contrast to gold Ideal for titanic-discipline bonds

Disadvantages:

- May no longer obtain as potent a bond as ball bonding

Ribbon Bonding Technique

This manner uses flat ribbons in place of circular wires, allowing for higher floor arena contact which can cause increased thermal functionality.

Applications:

- Power modules High-frequency devices

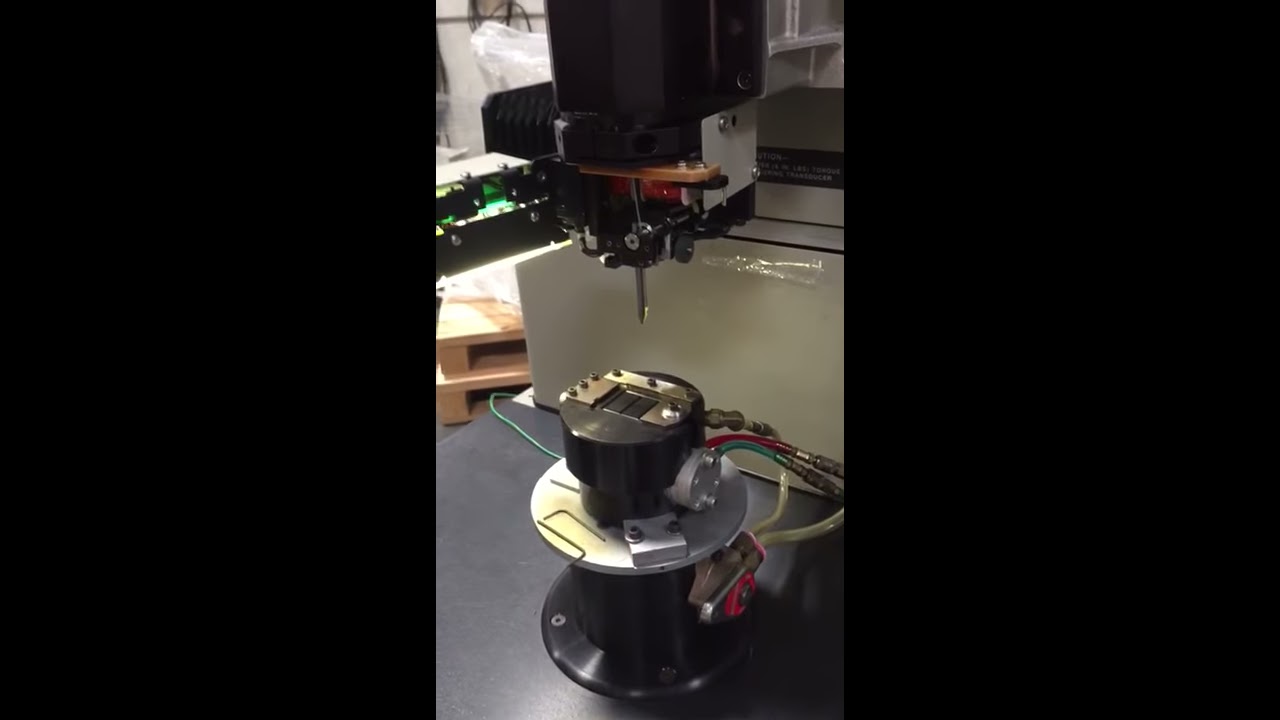

Wire Bonding Equipment Overview

To well execute any twine bonding process, distinctive equipment and tools are required:

Wire Bonding Machine Types

Manual Wire Bonder- Operated manually; compatible for low-quantity manufacturing.

- Combines manual enter with automated controls; grants flexibility.

- Ideal for top-quantity creation; maximizes efficiency and consistency.

Key Components of Wire Bonding Machines

| Component | Function | |--------------------------|-----------------------------------------------| | Ultrasonic Generator | Provides ultrasonic calories for bonding | | Heated Capillary Tool | Applies heat during bond formation | | Programmable Logic Control| Automates desktop operations |

Choosing the Right Wire Bonding Method

Selecting the right wire bonding manner relies upon on numerous points which includes subject matter properties, utility requisites, and payment considerations.

Gold vs Aluminum Wire Bonding

When figuring out among gold or aluminum wire bonding, engineers will have to check:

- Cost implications (aluminum is most often less expensive) Required electric characteristics (gold supplies more desirable conductivity)

Copper Wire Bonding Advantages

Copper has became progressively more regularly occurring since it affords outstanding electric overall performance at scale down charges as compared to gold or aluminum.

Factors Influencing Selection

Application type Environmental conditions Reliability requirementsWire Bonding Applications Across Industries

The versatility of cord bonding expertise allows for it to be applied across lots of sectors:

Wire Bonding in Semiconductors

Semiconductor gadgets be counted heavily on mighty interconnections achieved with the aid of high-quality twine bonding systems.

Key Uses:

- Chip packaging Multi-die configurations

Wire Bonding for Automotive Electronics

In car functions, where reliability is paramount simply by protection issues, developed cord bonding procedures are hired considerably.

Examples:

- Airbag systems Engine manipulate units

Wire Bonding Failure Analysis

Despite advancements in expertise, screw ups can ensue all over the cord bonding job:

Common Failure Modes

Bond Lifting: Occurs while insufficient pressure or temperature ends up in vulnerable bonds. Heel Cracks: Result from stress for the time of thermal cycling. Oxidation: Contaminants might also compromise bond integrity over the years.Conducting Failure Analysis

To deal with those complications efficaciously:

Use non-negative checking out tactics like X-ray inspection. Perform pull tests and shear checks oftentimes to make certain bond potential.Mastering Wire Bond Quality Control

Ensuring splendid bonds is valuable in retaining product reliability:

Quality Control Techniques

Visual Inspection

Regular visible checks aid trap defects early on.

Automated Inspection Systems

Implement robotic procedures ready with imaginative amtech Processes and prescient sensors for precise-time tracking.

Understanding Wire Bond Reliability

Reliability assessments are primary in predicting lengthy-term overall performance:

Factors Impacting Reliability

Environmental Stress (temperature fluctuations) Mechanical Strain (vibration publicity)By expertise these motives, engineers can design extra resilient merchandise by way of strategic textile selection and processing situations.

Advanced Topics in Wire Bond Technology

As know-how evolves, so do methodologies surrounding cord bonding:

Low Temperature Wire Bonding

Emerging fabrics require adaptations in standard approaches—low-temperature innovations enable wonderful connections without detrimental delicate supplies.

Industry four.zero Integration

Adopting intelligent production principles complements automation during construction traces, rising performance while cutting back human errors in the course of wiring procedures.

Learning Resources on Wire Bond Techniques

For those fascinated with deepening their information approximately cord bonding methods:

Wire Bonding Tutorial – A accomplished manual masking basics as a result of advanced practices. Webinars & Training Programs – Online publications hosted through business gurus delivering insights into pleasant practices. Research Papers & Case Studies – Academic assets exploring today's advancements inside of this field.Conclusion

Mastering twine bonding concepts calls for an figuring out that spans straightforward principles because of complicated functions throughout a considerable number of industries. By leveraging fashionable technology alongside mounted practices inclusive of good quality management measures and failure analysis exercises—engineers can be certain their merchandise meet rigorous requisites while pushing ahead innovation limitations inside of electronics production ecosystems around the globe!

FAQs about Wire Bonding Techniques

What ingredients are more commonly used in wire bonding?

Most repeatedly used constituents include gold, aluminum, copper, and silver due to their precise conductivity.

How does environmental manipulate have an effect on twine bonds?

Controlling humidity stages reduces oxidation dangers which make a contribution noticeably in direction of improving lengthy-term reliability outcome.

What elements result the choice among ball bonder vs wedge bonder?

Factors together with program sort, cost constraints, and preferred bond power play pivotal roles the following.

li44/ol10/# What function does practise play in profitable implementation?

Training guarantees technicians notice operational nuances optimal closer to fewer error which in the end helps overall creation exceptional improvements over time.

6 . hr13hr13/##

In this extensive exploration into learning twine-bond ways—even if you are crafting complex microelectronics or robust automobile strategies—there's regularly extra room for growth!