Introduction

The realm of twine bonding has substantially advanced, turning into an critical component to semiconductor packaging and digital assembly. Among the quite a number substances used in cord bonding, gold and aluminum have emerged as two widespread contenders. Understanding the nuances among gold vs aluminum in ribbon cord bonding is primary for engineers and brands alike, extraordinarily while deliberating elements which include rate, overall performance, reliability, and application. In this complete learn about, we are going to delve into the features of equally fabrics, discover their packages within the twine bonding system, and learn their advantages and disadvantages.

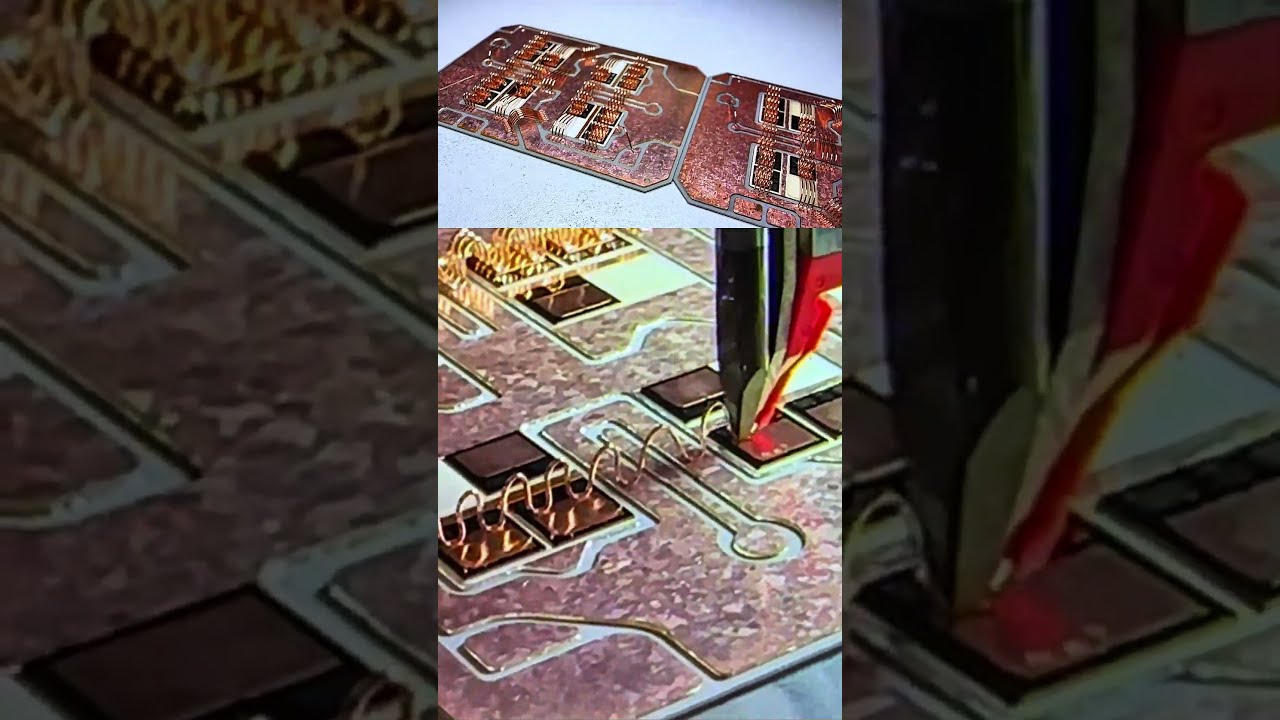

What is Wire Bonding?

Wire bonding is a means used in electronics to create electrical connections among a semiconductor chip and its kit or different areas. This course of comprises the usage of best wires to glue the die pad to the lead body or substrate. The wires can also be created from diversified ingredients together with gold, aluminum, copper, or silver.

How Wire Bonding Works

The twine bonding job ordinarilly comprises various steps:

Wire Selection: Choosing the appropriate materials situated on program standards. Bonding Process: Utilizing particular recommendations including ball bonding or wedge bonding to set up connections. Quality Control: Ensuring that the bonds meet targeted necessities thru inspection and trying out.Wire bonding technology has complicated appreciably through the years, with quite a number machines designed to automate this method for increased performance and precision.

Wire Bonding Techniques Overview

Several procedures exist inside the wire bonding process:

- Ball Bonding: Uses a small ball on the give up of a twine to make contact with the bond pad. Wedge Bonding: Employs a wedge-shaped instrument that presses down onto the surface of the bond pad. Ribbon Bonding: Utilizes flat ribbons in preference to circular wires, taking into consideration more advantageous flexibility in guaranteed packages.

The Role of Ribbon Bonding in Electronics

Ribbon bonding grants specific merits in phrases of pliability and simplicity of integration into challenging assemblies. It is fairly appropriate for top-frequency packages in which minimizing inductance is very important.

Gold Wire Bonding vs Aluminum Wire Bonding

When evaluating gold vs aluminum in ribbon cord bonding, it’s mandatory to understand a couple of causes inclusive of conductivity, mechanical houses, can charge-effectiveness, and environmental resistance.

Conductivity Comparison

Gold deals increased conductivity than aluminum. This thing makes gold cord greater precise for top-overall performance purposes the place signal integrity is indispensable.

Mechanical Properties

Aluminum tends to give better ductility in contrast to gold. Its skill to withstand mechanical rigidity without breaking makes it an pleasing selection for guaranteed purposes.

Cost Analysis

From a monetary viewpoint, aluminum cord is many times less steeply-priced than gold cord. Given that money is a meaningful thing in production judgements, many providers prefer aluminum even with its minimize conductivity.

Environmental Resistance

Both parts convey alternative degrees of resistance to environmental aspects together with oxidation. Gold does no longer oxidize without problems; therefore it keeps reputable connections over the years in contrast to aluminum which also can require added coatings or treatments to restrict corrosion.

Applications of Gold and Aluminum Wire Bonding

Gold Wire Bonding Applications

Gold wire bonding is predominantly used in:

- High-reliability systems Aerospace electronics Medical devices High-frequency RF circuits

Aluminum Wire Bonding Applications

Aluminum twine bonding reveals its place in:

- Consumer electronics Automotive components General-objective semiconductor packaging

Understanding Different Types of Wire Bonds

Different sorts of twine bonds are central based on special program specifications:

Ball Bonds: Ideal for high-reliability packages because of their potent interfacial adhesion. Wedge Bonds: More victorious for cut back-profile applications where peak constraints exist. Ribbon Bonds: Suitable for pressure modules due to their giant floor edge bettering thermal dissipation.Wire Bonding Equipment Overview

Various machines are employed for the duration of the twine bonding strategy:

- Manual Wire Bonders Semi-Automatic Machines Fully Automatic Systems

These machines differ structured on complexity and throughput talents depending upon creation wishes.

Wire Bond Quality Control Measures

Ensuring first-rate bonds consists of rigorous inspection strategies together with:

- Visual inspections Pull tests Shear tests

Wire Bond Failure Analysis

Failure analysis performs a indispensable function in knowing possible troubles that might arise in the time of manufacturing:

Incomplete bonds because of the insufficient ultrasonic strength. Oxidation top to vulnerable interfaces. Mechanical rigidity inflicting bond lifting or heel cracks.By addressing those challenges via nice manage measures, producers can amplify the reliability in their products noticeably.

Comparative Study: Gold vs Aluminum Ribbon Wire Bonding Techniques

In this phase, we will be able to instantly compare ribbon wire bonding approaches utilizing equally gold and aluminum material across a range of metrics inclusive of bond power, thermal overall performance, charges related to every one type of cloth used throughout construction methods – revealing how they stack up opposed to both different less than designated occasions!

| Metric | Gold Ribbon Bonds | Aluminum Ribbon Bonds | |-------------------|------------------------|-------------------------| | Conductivity | Highly conductive | Moderately conductive | | Cost | Higher | Lower | | Ductility | Less ductile | More ductile | | Environmental Resistance | Excellent | Moderate |

As visible from this table comparison above; even though gold may possibly present top-quality electric performance traits — it comes at an improved monetary burden which some producers might not in finding justifiable based mostly on their product designs!

Conclusion on Gold vs Aluminum in Ribbon Wire Bonding

In abstract; whereas the two alternate options show targeted advantages & drawbacks — determination in the end relies upon distinctive project necessities! Factors like cost constraints versus preferred efficiency metrics should still book engineers when deciding on regardless of whether they must settle on one cloth over an extra (gold vs aluminum).

The ongoing evolution within this container continues beginning doorways toward leading edge suggestions aimed at recuperating common performance while asserting excessive necessities at some point of creation strategies worried inside of ultra-modern-day electronics!

FAQs

What are traditional functions for gold twine bonding?

Gold wire bonding is aas a rule used in aerospace electronics and scientific devices resulting from its reliability and splendid conductivity.

Is aluminum inexpensive than gold for wire bonding?

Yes! Aluminum sometimes costs less than gold making it appealing for price range-mindful tasks requiring enough overall aluminum wire bonding performance degrees with no breaking bank bills!

What causes have an impact on my option among gold vs aluminum?

Consider sides like conductivity desires as opposed to funds barriers which include environmental matters ahead of making your choice on the topic of which drapery highest suits your utility's necessities!

How does temperature impact bond reliability?

Extreme temperatures can impression bond integrity resulting either from thermal expansion discrepancies finest against disasters or weakening adhesive forces offer at these elevated stages skilled at some stage in operation cycles and so forth…

What inspection programs make certain caliber keep an eye on in the time of production?

Common practices incorporate visual inspections alongside mechanical pull/shear checking out designed primarily determine adherence principles being met earlier finalizing any product lines capable distribution channels and so on…

Can I use each substances interchangeably?

Not unavoidably! Each subject material possesses distinct qualities influencing total functionality as a result substituting one without delay may want to lead problems requiring redecorate efforts verify compatibility across current frameworks worried right through assembly ranges etc…

This entire observe on "Gold vs Aluminum in Ribbon Wire Bonding" highlights considered necessary elements essential for market experts navigating due to choices feasible as of late at the same time refining processes evolved over decades beyond optimal innovation forward!